|

|

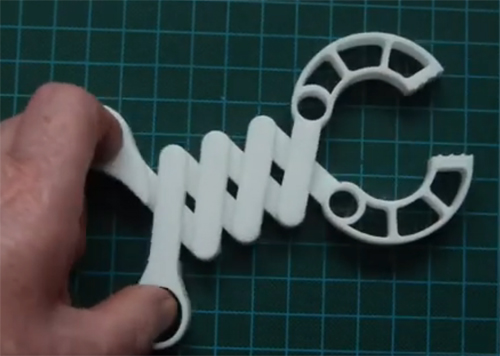

X-axis belt tensioner. Thingyverse 2986144 by Makechetti. This was one of my earliest prints. You can clearly see the treads in the inside of the ring on the left. The threads on the strangely shaped part on the right are more obvious in the video below. This part also has hexagonal recesses which capture a nut to prevent it from spinning. |

|

Video showing threads on both parts. Jane's hands showing two parts threaded together and recess for M5 nut.

Click on the thumbnail to play the video in You Tube.

CLOSE the YouTube window to return to this page.

|

|

|

|

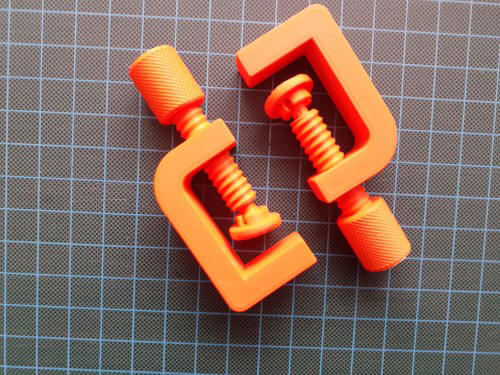

3d printed G-clamps. Thingyverse 1673030 by johann517 These are printed in three parts, the U-shaped frame which has a threaded hole to take the threaded rod with the knurled nut at the end. The protector on the end makes two flat surfaces to hold the clamped object. |

|

|

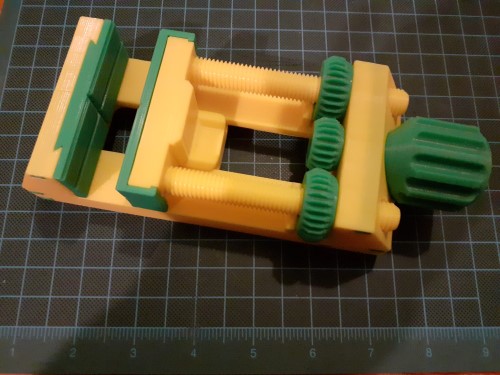

100% 3d printed Vice Thingyverse 2064269 by TheGoofy This vice is made from 100% 3d printed parts, right down to the pins which holds it together. The large spindle on the right turns the small centre knurled knob which in turn rotates the two outer knobs in the opposite direction. As they rotate, they pull the two screwed rods in or push them out making the jaws of the vice either open or close. It is ideal for holding printed circuit boards while they are being soldered. The jaws are about 100mm wide and open to about 120mm. |

|

Video showing the jaws opening and closing. Click on the thumbnail to play the video in You Tube.

CLOSE the YouTube window to return to this page.

|

|

|

|

Extending Grabber - printed as you see it!! Thingyverse 3886887 by 3D Toys. Don't know if this has any practical uses but it illustrates another of the amazing tricks which 3d printers are capable of. All the hinges in this model are printed in situ. What you see is the print which came off the printer bed, nothing else has been added. |

|

The Grabber in Action. This video shows how freely the hinges move. Click on the thumbnail to play the video in You Tube.

CLOSE the YouTube window to return to this page.

|

|

|

|

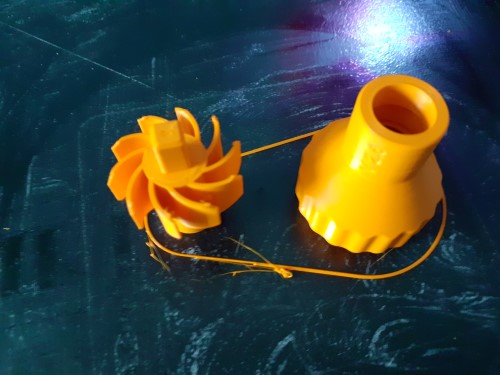

Print head nozzle removing tool. Can't find where I sourced this print. 3d prints are made by pushing plastic filament, heated to about 200oC, through a nozzle which has a hole 0.4mm in diameter. The nozzle must be heated to this temperature if it is removed or replaced. This tool allows a 1/4" socket to be used on the nozzle. The "paddle-wheel" like part on the right allows the socket holder to be used like a torque wrench. Unlimited force can be used to unscrew nozzle but limits the torque which can be used when tightening. |